THE STORY BEHIND BEST ELECTRIC MACHINE

Our Mission:

Innovate For Our Clean, Efficient, and Sustainable Energy Future!

The Story Behind the Founder and CTO of Best Electric Machine, Frederick W. Klatt, And the Inventor of SYNCHRO-SYM Technologies:

After experiencing the first oil embargo in 1973, while attending the University of California, Berkeley, as an engineering post-graduate student studying nuclear magnetic resonance for medical imaging, and then, followed by the second oil embargo of 1979, I was committed to free my dependency on fossil fuel by building an electric vehicle (EV) for daily commuting. To my surprise, electric motor design and electronic-computer control design were two very disparate disciplines, which hasn’t changed much since, and as a consequence, the only readily available EV motor at the time was the rheostat controlled, electromechanically commutated Universal Motor that was invented in the late 1800’s.

Well aware of the switch-mode power supply (SMPS), which were quickly replacing the large, inefficient linear power supply in mainframe computers, I conceptually realized that electronically modulating a modified SMPS with the new microprocessor control technoloby would provide a much more practical, reliable, and efficient means of producing variable frequency and voltage sinewave excitation for EV motor control. Already having a strong background in electronic and computer design (i.e., analog, digital hardware/software design) and electromagnetic field theory, I immersed myself in the self-study of electric machines (i.e., electric motor, generator, and transformer) for applying this novel control means but quickly realized that another level of motor control was needed to avoid the problematic reliance on slip-induction by automatically maintaining the port voltage, excitation frequency, speed, and torque in accordance with the synchronous speed relation with an active winding set on the rotor and stator, respectively.

Surprisingly still being investigated today, my first control concept was the doubly-fed cascaded electric slip-induction motor for the brushless propagation of speed synchronized multiphase excitation to the rotor active winding set by using the electromagnetic computation of one of the cascaded motors as a multiphase rotor winding excitation generator (mREG). My research and experimentation showed the dual cascaded electric induction motor method had some formidable loss, cost, size, and stability problems, such as: 1) the reliance on slip-induction (i.e., asynchronous operation), which disappears about synchronous speed without introducing an artificial slip-induction means by the extraordinary and inefficient “unlike pole pair” circuitry and control means, 2) the brushless excitation in accordance with the synchronous speed relation, including supplying phase controlled DC at synchronous speed or disappearing AC about synchronous speed, 3) the instability by random rotor or line perturbations during synchronous operation, and 4) the opposing torque between the dual cascaded machines.

While trying to solve these problems, my eureka moment of “invention” appeared, “Simply reduce the size and mutual inductance (and associated torque) of the mREG while increasing its efficiency with a high frequency carrier design provided by a unique direct AC-to-AC synchronous modulation-demodulation method and as a result, the four imposing problems were solved!”

After years of study, research, development, prototyping, and publication, which was debt financed through my technical consulting firm, I patented SYNCHRO-SYM, which is the only practical and stable, brushless “symmetric” multiphase wound-rotor “synchronous” doubly-fed electric machine system with the optimized symmetry of both rotor and stator actively contributing additional working power to the electromechanical energy conversion process, but only by postulating the practical invention of a brushless real time emulation controller (BRTEC) for stable and synchronous operation from sub-synchronous to super-synchronous speeds, which includes synchronous speed and zero speeds. Ironically, the classic introductory 101 study of electric machines begins with the brushless symmetric multiphase wound-rotor “synchronous” doubly-fed electric machine system, now called SYNCHRO-SYM, but becomes the 101 follow-on study for all other electric machines by deoptimizing SYNCHRO-SYM’s electromagnetic symmetry with the “electromagnetic asymmetry” of a “passive rotor” of either slip-induction dependent windings, permanent magnets, DC field windings, and reluctance saliencies. Nearly a century of classic electric machine 101 study, research and publication, which I reimagined into practical reality by a regimen of prototyping and invention, has proven that SYNCHRO-SYM provides twice the constant torque speed (i.e., maximum load speed or MLS) for a given torque, port voltage and excitation frequency (i.e., 7200 RPM with 2 poles at 60Hz versus 3600 RPM for the asymmetric electric machine system of all others), which calculates to twice the power density and octuple the peak toque at half the cost and loss per unit of continuous power rating in the same packaging (less rare-earth permanent magnets).

With the unique perspective of an electronic circuit and computer control guru but a self-taught electric machine expert, my electric motor innovation was not influenced by the subliminal control of customary electric motor practice or innovation by a global adversary seeking world dominance. For example, 1) customary practicing experts always confuse SYNCHRO-SYM with the so-called “doubly-fed,” multiphase wound-rotor “slip-induction” electric machine system, which is not a brushless “symmetric” doubly-fed “synchronous” electric machine system but instead, is an asymmetric singly-fed “asynchronous” or self-induction electric motor with a multiphase slip-ring assembly and known discontinuity and instability issues and 2) RE-PM electric motor systems have rapidly replaced slip-induction motor systems, particularly in EVs, to eliminate the loss, cost, and size of magnetizing MMF but instead of comparably optimizing slip-induction electric motor system, magnetizing MMF is ironically being less efficiently re-introduced into RE-PM electric machine systems to regain the coveted attribute of field weakening. As a result, I invented a totally new electric machine circuit and control architecture, called SYNCHRO-SYM, that symmetrically merges electric machine and electronic control disciplines into an inherently integral electric motor system design. In contrast, the asymmetric electric motor system is an electric motor component and a disparate electronic control component, which at best, is distinctly mounted on the motor chassis for today’s so-called “fully integrated smart motor.” Also, I had to redefine some customary electric machine terminology, such as synchronous electric motor, doubly-fed, and slip-induction, to accurately describe the novel operating principles of SYNCHRO-SYM.

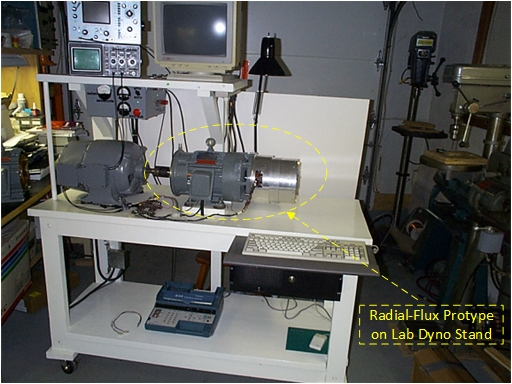

For multiple progressive stages of initial prototyping, I performed the research and development (R+D) of SYNCHRO-SYM’s unique electronic control and electric machine (i.e., electric motors, generators, and transformers) principles by modifying surplus electric motors and resolvers. But as the prototypes became more sophisticated, contract manufacturing was employed, which proved to be costly and untimely with long lead times and re-iterations.

As an early pioneer of low and high frequency, high power axial-flux electric machines, who understood their benefits long before the fad of today, I conceived, researched and developed, and then patented the only 3D Printer, called MOTORPRINTER, for the additive manufacture of axial-flux electric machines, which unlike customary 3D Printer, uses optimized, premanufactured feedstock materials of high performing non-crystalline (e.g., amorphous, nanocrystalline, etc.) metal ribbon, structural materials, and magnetic wire, which are compatible with the additively manufactured electric machine without damaging the delicate electromagnetic properties, for low-cost, inhouse prototyping and just-in-time additive manufacturing of SYNCHRO-SYMs. MOTORPRINTER is in fabrication, today.

In conclusion, I am increasingly annoyed by the constant introduction of so-called “new” high performance electric motor technology by simply applying different port voltages, excitation frequencies, MLSs, or available packaging techniques, such as the rare-earth permanent magnets (RE_PM) or axial-flux formfactor, to the same “me-too” asymmetric electric motor system, which would always result in similar performance gain if equally applied between contestants, but more concerning, I am annoyed by the increasing application of RE-PMs as the best electric motor solution, which are monopolized by a global adversary seeking world dominance with human rights, environmental, and geopolitical violations that at the very least, is setting back years of productive climate change efforts. In response, I formed the essential lean, creative team of functional experts with a mutual urgency to prudently and ethically bootstrap the engineering, production, and sales of SYNCHRO-SYM, which is without RE-PMs but inherently provides double the power density and octuple the peak torque at half the cost and half the loss per unit of package continuous power rating of any other electric motor system package.