SYNCHRO-SYM Technologies

– Simple SYNCHRO-SYM CONOPS –

Our Mission:

Innovate For Our Clean, Efficient, and Sustainable Energy Future!

Simple CONOPS of SYNCHRO-SYM?

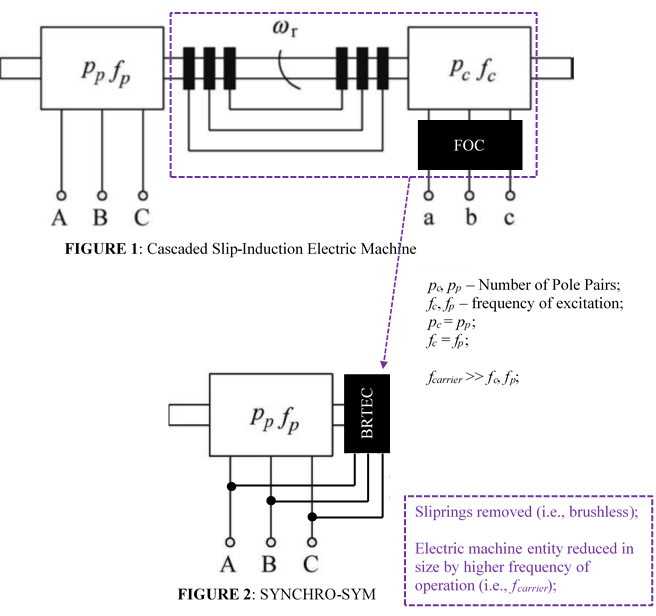

The “Overview of Research and Development Status of The Brushless Doubly-Fed Machine System” illustrates the evolution of the doubly-fed electric machine systems that began with the rotor shafts of two multiphase, wound-rotor slip-induction (i.e., asynchronous) doubly fed electric machines (with multiphase slip-ring-brush assemblies) connected in cascade and running together under a derivative of inexact estimating Field Oriented Control (FOC) (as shown in FIGURE 1). Note: Slip-induction is rotor excitation (or mutual induction) due to the low asynchronous speed (or slip) between the rotor and stator winding sets. Since both electric machines are position-dependent-flux rotating transformers, all phase windings of each electric machine are mutually coupled with each other across the air-gap by slip-induction in accordance to the synchronous speed relation (±WS±WR±WM=0, where WR is the electrical angular frequency of the rotor winding excitation, WS is the electrical angular frequency of the stator winding excitation, and WM is the mechanical angular frequency of the rotor). With the rotors connected (WM1 = WM2), the frequency from the rotor multiphase winding of one multiphase slip-ring wound-rotor doubly-fed electric machine exciting the rotor multiphase windings of the second multiphase slip-ring wound-rotor doubly-fed electric machine through their “multiphase” slip-ring assemblies will automatically and sensorlessly remain speed-frequency-phase synchronized at any speed. But because slip-induction ceases to exist (or becomes irrelevant) about synchronous speed (Wr = 0), the cascaded electric machine configuration cannot controllably ride through synchronous speed to super-synchronous speed (without extraordinary control means, such as a) brushless real time emulation control (BRTEC), b) unlike pole-pair arrangements to guarantee slip-induction, or c) prime mover propulsion), and as a result, the cascaded electric machine (or any electric machine), which relies exclusively on slip-induction, cannot legitimately satisfy the criteria of a “practical synchronous” wound rotor doubly-fed electric machine system that contiguously and stably operates with constant controllable torque from sub-synchronous to super-synchronous speed, including at or about synchronous speed. While comprising the complexity and sizable real estate of two rotors, two stators, and two multiphase slip-ring assemblies with equally sized and rated electric machines that are without special excitation, such as unlike pole-pairs to guarantee slip-induction at any speed, the torque from each electric machine would equally oppose each other but may provide the power of one electric machine under certain operating circumstances.

After years of study, it was learned that dual cascaded electric machines with unlike pole-pairs (i.e., pc != pf) would mitigate torque fighting (and would offset their common synchronous speed to guarantee slip-induction across a reasonable speed range but never about the pole-pair synchronous speed) and as a result, the so-called brushless doubly fed induction or reluctance electric machine (BDIM) was born, although torque fighting and mutual inductive cross coupling between the dual armatures of unlike pole-pairs (both residing on the stator) could never be completely addressed. With continued research and development, the BDIM became a dual stator armature of unlike pole-pairs configuration with a magnetic focusing rotor that reduces (but never eliminates) the mutual cross coupling between the dual stator armatures but nearly doubling the diameter with two active stator winding sets. Still, the BDIM is rising in popularity for some applications due to the unique attributes of doubly fed electric machines (compared to singly-fed electric machines), such as robustness, reliable operation, ease of maintenance, adjustable power factor (e.g., leading, lagging, or unity), and small converter capacity with relatively low cost.

In accordance with the simple Detailed Concept of Operation (CONOPS) of the patented architecture (as shown in FIGURE 2) comprising a brushless, bi-directional, sensor-less and automatic controller (i.e., BRTEC), which replaces the slip-ring assemblies, the second multiphase wound rotor doubly fed electric machine, and the FOC components in the dotted box in Figure 1, SYNCHRO-SYM configures one of the dual cascaded electric machines as an electromagnetically symmetrical “high frequency and low mutual inductance” position-dependent-flux transformer (PDF-HFT) with individual modulators-demodulators (or simple high frequency bi-directional electronic choppers) on each side of the air-gap that modulate and demodulate the high frequency carrier (i.e., fcarrier) of the individual phase signals in either direction with proprietary techniques, which inherently provide pure sinusoidal waveforms bi-directionally driving the utility power and the windings (that is the brushless real time emulation controller).

Based on the ratio between the low and high operating frequencies of the cascaded electric machines, physics dictates that the high frequency electric machine entity (i.e., PDF-HFT) is extremely more compact with fewer winding turns and lower air-gap flux density for extremely lower mutual inductance, associated torque, and electrical loss compared to the low frequency torque producing electric machine entity (i.e., the torque producing multiphase wound rotor doubly fed electric machine). In accordance to Faraday’s Law, the product of the core winding turns, the core flux density, the core size/weight, and the core mutual inductance are inversely proportional to the operating frequency and as an example, with 24 kHz of high frequency excitation applied to the high frequency electric machine entity (i.e., PDF-HFT) and with 60Hz of low frequency excitation applied to the low frequency electric machine entity (i.e., a frequency ratio of 400 to 1), the mutual inductance (and torque production) of the low frequency electric machine entity would be 400 times the mutual inductance (and torque production) of the high frequency electric machine entity. Therefore, the core size/weight, winding turns, or flux density of the high frequency electric machine entity would be typically reduced by nearly 8x; but more importantly, the multiphase wound rotor of the low frequency electric machine entity is driven directly (via the high frequency electric machine entity or PDF-HFT) and as a result, the low frequency electric machine entity pumps out the power of two equally rated active winding sets on the rotor and stator, respectively, or twice the power (and power density). With BRTEC (which inherently includes an absolute position resolving position-dependent-flux high frequency rotating transformer (PDF-HFT) completely replacing the low frequency “cascaded” multiphase slip-ring assembly electric machine example of FIGURE 1), the cascaded electric machine of FIGURE 1 (with the power of one electric machine) becomes the FIGURE 2 depiction with double the power (i.e., power of dual armatures) and with the multiphase slip-ring assembly replaced by BRTEC, the total system power density double with half the amount of material (cost) and electrical loss. In accordance with the physics of a balanced dual-ported transformer, the torque current flux on each side of the airgap would cancel and as a result, the core does not saturate with increasing torque current for the highest peak torque density (and peak power density) potential of any other electric machine. Also, there would never be a) the loss of, b) the stochastic dependency on, or c) the instability of slip-induction about synchronous speed because of the difference between the low and high operating frequencies. More importantly, the individual rotor phase winding excitation (or even the level of DC at synchronous speed) would be sensorlessly and automatically (i.e., real time emulation) phase position dependent (as programmed) for direct angular speed and phase synchronized excitation of the rotor active multiphase winding set and precise torque angle control, regardless of the position or speed of the rotor shaft, including at or about synchronous speed, which eliminates any stochastic control dependency on slip-induction. As only provided by BRTEC, SYNCHRO-SYM becomes the only practical stable electromagnetically symmetrical multiphase wound-rotor “synchronous” doubly-fed electric machine system.