THE STORY BEHIND BEST ELECTRIC MACHINE

Our Mission:

Innovate For Our Clean, Efficient, and Sustainable Energy Future!

ELECTRIC MOTOR SYSTEM INNOVATION IS ESSENTIAL:

Today’s advances in electric motor system innovation is technically limited to “me-too” electric machine systems with the “non-optimal asymmetry” of a wasteful “passive rotor” with either slip-induction windings, reluctance saliencies, rare-earth permanent magnets (RE-PM), or DC field windings, which cannot contribute additional active power to the electromechanical energy conversion process along with the universally essential “active stator,” but with a new twist, ethically searching for electric motor system innovation that will eliminate the RE-PM electric motor system, which is prejudicially monopolized by a global adversary exploiting electric motor innovation, labor, environment, and geopolitics:

- “Automakers outside China are scrambling to develop electric motor designs that use no permanent magnets, partly because the magnets require rare earths, and mining rare earths causes pollution. It’s also partly because the mining is done in China, a formidable automotive competitor” (12-May-2021)

- “As the world builds more and more electric cars and trucks—and electrifies other modes of transit—a race is underway to build the ideal, mean-and-green motor. The goal is a traction motor that’s at least as powerful, reliable, and lightweight as today’s industry standard rare-earth permanent magnet synchronous motor.” (15-Mar-2024)

Unlike today’s strict practitioners of available asymmetric electric motor system technology, theoreticians of classic electric motor study have realized for nearly a century that the optimal symmetry of an “active rotor” with another ”active winding set,” which contributes an additional increment of working power along with the stator active winding set by the stabilization of a theoretical “brushless real time emulation controller (BRTEC)” invention, as only provided by SYNCHRO-SYM, would show twice the power density and octuple the peak torque at half the cost and half the loss per unit of power rating with the same design, packaging, and manufacturing as any asymmetric electric machine system. Without an understanding of BRTEC for realizing the only symmetric electric motor system, practitioners always confuse SYNCHRO-SYM with the so-called multiphase wound-rotor, doubly-fed “slip-induction” electric machine system, which like the RE-PM electric machine system, is another example of the inferior performing “me-too” asymmetric electric machine system.

For advancing electric motor system innovation, the question isn’t “Will the electric vehicle (EV) dominate the transportation market in order to continue advances in electric motor system innovation?” Instead, the question should be “What is the best propulsion drivetrain solution for any vehicle, regardless of fossil, hydrogen or battery fueled,” which will more efficiently and reliably replace the “mechanical drivetrain” with gearboxes and differentials, which is also used in today’s so-called electric vehicles to reduce the amount of RE-PM materials with a smaller, ultrahigh speed asymmetric electric motor system? By ignoring the intimidating mechanical drivetrain infrastructure, most would choose the “electromagnetic drivetrain” with directly driven (gearless) electric motor and generator systems and a ballast for energy recovery as the best solution.

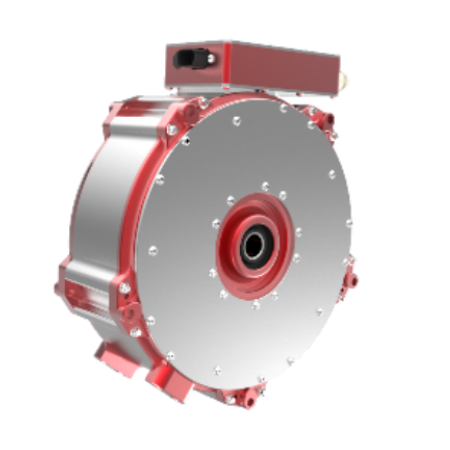

As the following rendering shows, two SYNCHRO-SYMs can replace the typical EV high speed asymmetric electric motor system package with the essential electronic controller, speed-reduction gears, and differential (e.g., Vitesco EMR-3 or EMR-4) without increasing the original package size, loss, or cost but with twice the power, twice the reliability, half the complexity, and precision independent torque vectoring of the two wheels: