SYNCHRO-SYM Technologies

– SIMPLE QUALITATIVE PROOF –

Our Mission:

Real Innovation for Our Clean, Efficient, and Sustainable Energy Future!

Powering Our World with Less Energy and Carbon Footprint, Plug & Play Sustainability, and Inherent Modularity!

SIMPLE QUALITATIVE PROOF:

In accordance to Lorentz Force Law, all electric machines produce force with two orthogonal flux (or current) vectors, which are the Torque Flux produced by the torque magneto-motive-force (MMF) and the Magnetizing Flux. Magnetizing Flux is produced by a) Magnetizing MMF (i.e., product of current and winding turns), b) the product of rare-earth permanent magnet (RE-PM) coercivity and its depth, or c) the magnetic path with reluctance change. Only RE-PMs persistently produce Magnetizing Flux (i.e., product of coercivity and RE-PM depth) without the electrical loss of magnetizing electrical MMF power, which has driven its widest application. In contrast, the reluctance, slip induction, or dc field wound asymmetric electric machines show similar Magnetizing Flux electrical loss but only the Symmetric electric machine system, as only provided by SYNCHRO-SYM, which operates with half of the Magnetizing MMF on the rotor and stator, respectively, shows half the electrical loss associated with Magnetizing MMF. The slip-induction asymmetric electric machine has the additional burden of a stator that must be additionally power rated (and sized) for the power of the rotor. All electric machines have some degree of core loss, including RE-PM electric machines.

The total loss, cost, and size of an “asymmetric electric machine system” is the sum of the loss, cost, and size associated with the “active stator” and “passive rotor” assemblies but the total power rating is determined by the single stator active winding set (i.e., singly fed). Without including the associated loss, cost, and size of the fully rated electronic controller of singly-fed electric machine system, which shows significant compounding impact to the total system loss, size, and cost, and also, by reasonably normalizing the loss, cost, and size of the rotor or stator assemblies to a unit of 1 (per KW of power rating), the asymmetric electric machine system would reasonably show 2 normalized units of loss, cost and size per KW of power rating (i.e., 2 normalized units of loss, cost, and size for the active stator and for the passive rotor divided by 1 unit of power rating). Similarly, the best case assumption for the asymmetric electric machine system is the RE-PM electric machine system, which assumes a rotor loss of only 10% of the Induction asymmetric electric machine system.

By conveniently replacing the passive rotor and bearing assembly of slip-induction dependent windings, rotor saliencies, DC field windings, or RE-PMs of the asymmetric electric machine system with a rotor core and bearing assembly comprising another active winding set as found on its universally essential active stator assembly for primary torque and working-power production, all of which are under the same air-gap flux density, the same air-gap effective area, the same voltage and frequency of excitation, and the same speed and torque design, the resulting “symmetric circuit and control architecture” of SYNCHRO-SYM (as only possible with BRTEC) comprises an “active winding set” on both the stator and rotor assemblies, respectively, providing double the total power rating (i.e., doubly-fed) as the single “active stator assembly” of the asymmetric electric machine system. Without including the associated loss, cost, and size of the known characteristic of “half rated” electronic power conditioning for symmetric doubly-fed electric machine control, which would show significantly lower compounding loss, cost, and size impact than the characteristic “full rated” controller of the single fed asymmetric electric machine system, the symmetric electric machine system would reasonably show 1 normalized unit of loss, cost, and size per KW of power rating (i.e., 2 units of loss, cost, and size for both the rotor and stator active winding sets divided by 2 units of power rating), which is half the loss, cost and size of the reasonable case assumptions without considering the superior loss, cost, and size performance of BRTEC over FOC.

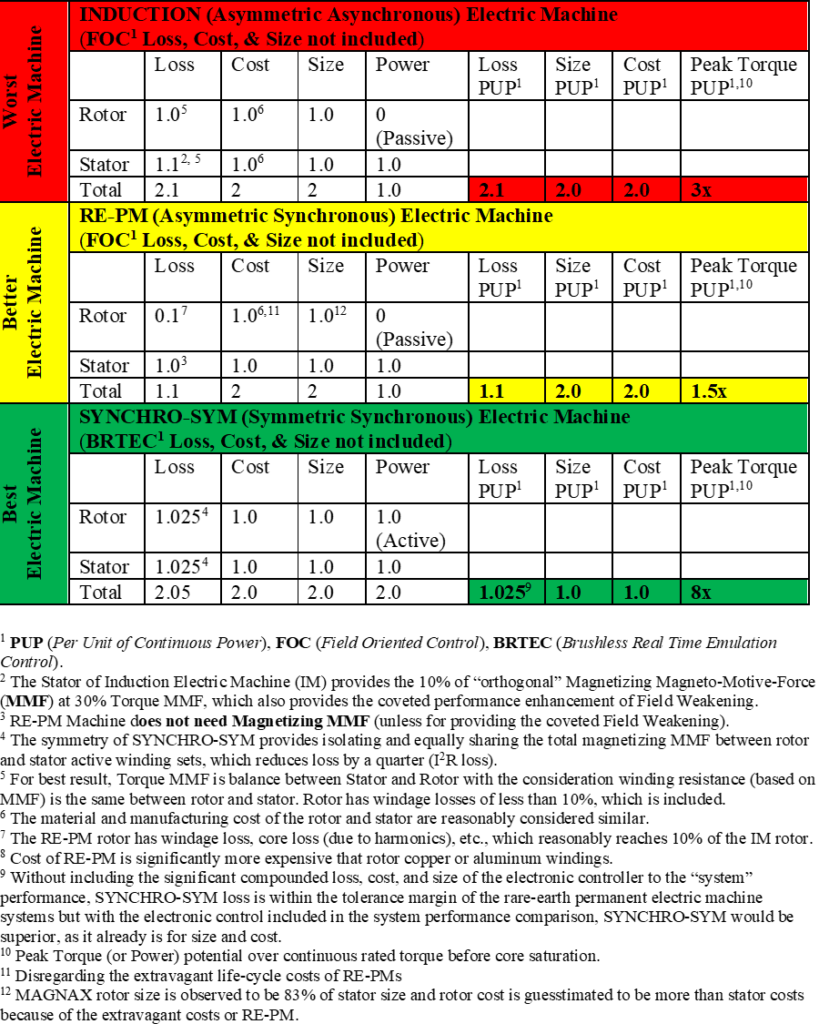

By a simple qualitative method of proof, the following table provides a graphic view of the previous analysis to conveniently show that SYNCHRO-SYM will always be at least smaller, as efficient, and less costly than any asymmetric electric machine system, such as the rare-earth permanent magnet (RE-PM) electric machine system, for a given power rating by as much as half as large, half as costly, and half as lossy. By introducing the significant compounded loss, cost, and size associated with the half rated electronic controller (system) of SYNCHRO-SYM verses the full-rated electronic controller of the asymmetric electric machine system, SYNCHRO-SYM will always show significant performance improvement over any asymmetric electric machine system, including the RE-PM electric machine system. For instance, operating under the same port voltage for equitable comparison, the full rated electronic controller of the asymmetric electric machine system would require full current control to meet full power rating in contrast to the half-rated (and half current) BRTEC, which provides SYNCHRO-SYM a significant I2R loss advantage. Also, the electric machine entity power loss would be compounded as it passes through the controller.