Invest

SYNCHRO-SYM Technologies

– PRODUCT PURCHASE –

– COLLABORATIVE DEVELOPMENT –

Our Mission:

Innovate For Our Clean, Efficient, and Sustainable Energy Future!

BEST ELECTRIC MACHINE (BEM) VALUE:

Our Distinctive Value Proposition: Whatever the verified power density and peak torque claims of any other electric motor system with a given excitation frequency, voltage, constant torque speed range, and package design, only the patented symmetric circuit and control technology of SYNCHRO-SYM will double the performance of the claims at half the loss and half the cost per unit of power rating, as was proven by nearly a century of classic electric motor and generator study, research, and publication and reimagined to practical reality by a regimen of BEM prototyping and invention!

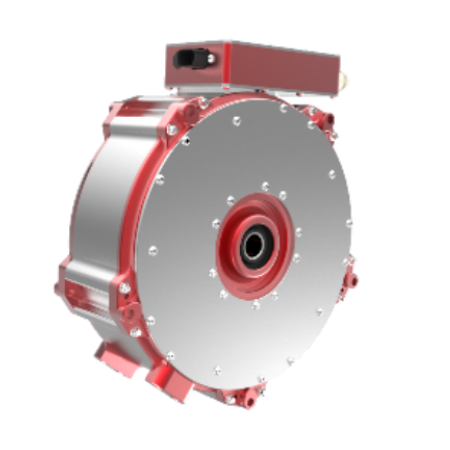

Today: Only SYNCHRO-SYM “Total System” Power Density reaches over 66 KW/L, Specific Power reaches over 16 KW/Kg, Efficiency reaches over 96%, and Cost is halved per unit of power rating with the same design specification (e.g., 800 volts DC, 4000 RPM, and 1.25T flux density), with the same electric machine package and performance enhancing techniques, with the compounding size, loss, and cost of the electronic controller “extraordinarily” included, and without precious rare-earth permanent magnets or superconductor electromagnets!

Tomorrow: Only SYNCHRO-SYM will continue to effectively double the advertised performance gain and half the cost per unit of power rating of any present or future electric machine packaging and performance enhancing techniques available to all electric machine systems, such as the performance and cost of emerging wide-bandgap semiconductor (WBG) switches, by “uniquely” enabling the rotor to be an additional “active power” contributor to the electromechanical energy conversion process along with the universally essential active stator! When superconductors become a practical reality, the fully electromagnetic SYNCHRO-SYM will be the only electric motor system of choice!

Soon: When fabrication is completed (circa late 2024), MOTORPRINTER will eliminate the typical, highly capitalized, exploited labor, industrial factory for electric motor manufacture while providing inhouse, just-in-time, additive manufacture of any size SYNCHRO-SYM with seamless incremental production scaling, high capacity thermal management, and convenient power stacking!

Unlike the traditional product partnership with a who’s who team of marketeers, which is essential to cunningly promote their “me-too” electric motor system product as having higher performance than another “me-too” electric motor system with the same packaging and performance enhancing techniques, a BEM product partnership is with our lean, prudently committed team with 1) the functional expertise to candidly promote BEM’s re-imagined electric motor system products to the $1.4T electric vehicle motor market with our straight-forward “Bootstrap Verification, Validation, and Unveiling Plan” and 2) with the ethical resolve to provide the only superior alternative to the anecdotally chosen rare-earth permanent magnet (RE-PM) electric motor system that has been monopolized by a global adversary seeking world dominance with harmful exploited labor, environmental, geopolitical, and motor innovation controlling consequences.